The cold process soap-making technique is known for thousands of years. The name soap comes from Latin sapo, and the chemical reaction of soap making is called saponification.

Saponification is a reaction between hot alkali solution, usually sodium hydroxide, and fatty acids from oils or natural fats resulting in fatty acid salts and by-product glycerin. Glycerin is a non-toxic, natural humectant that keeps the skin hydrated and soft.

Cold process soap making does not use any additional external heating to speed up the saponification, unlike the hot process. The saponification in CP usually occurs within the first 48h. The reason why cold process soaps have a curing time of at least several weeks is that water evaporates from the soap making it harder, soap develops a crystalline structure and overall soap quality improves. So the longer soap cures, the better. From my experience, soaps that cure longer have stronger bubbles, creamier lather, and last longer.

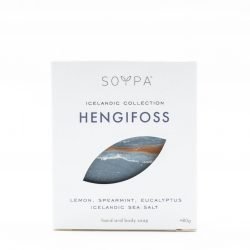

All Soypa soaps cure for at least 4-6 weeks, as the quality of the soap bars is extremely important and curing time has an important role in getting a finer soap.

SO HOW DOES THE SOAP MAKING PROCESS LOOKS?

First, safety equipment includes gloves, long-sleeved clothes, an apron, and a mask. Protecting yourself from potential danger is a must-do. Sodium hydroxide is a very strong chemical and can cause serious injuries.

My soap making equipment includes stainless steel pots, pitchers, silicon molds and spatulas, spoons, scale, and surface protection.

Before mixing, it is important to have all the ingredients ready, like essential and carrier oils, pigments, and lye solution, otherwise, things can go wrong and the results might not be as wanted.

When everything is ready it is time for saponification by adding a lye solution to the oil mix. To speed up the reaction and get a thicker batch, many soap makers use a hand mixer. At this point, things can differ a bit depending on if you’re making some design or not, but it is the moment when essential oils and pigments are added to the soap batch.

After the soap batch is prepared, it is poured into the soap molds and left for around 24h to become solid. Sometimes it takes longer, depending on the oils used and the thickness of the batch.

The next step in a soap process is cutting. I own a single-wire bamboo soap cutter so each batch is cut one by one, which brings the excitement of expectation of how the next soap looks.

After some time, soaps get stamped and are stored on the shelves to cure for several weeks.

BEKIJK DE PRODUCTEN